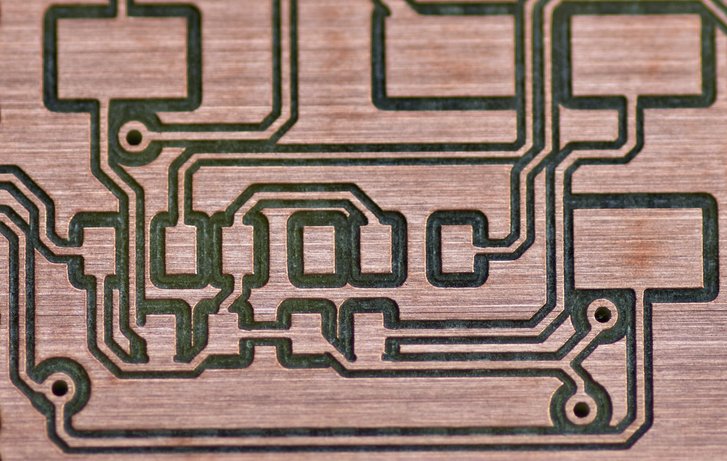

A printed circuit board composed of several layers

A multilayer is made up of multiple layers that are laminated together to form a printed circuit board. The outer layersof a multilayer are usually single-sided PCBs, whereas the inner layers are double-sided materials. Insulating layers, so-called prepregs,are inserted between the conductive layers. Up to four layers can be through-hole plated in a chemical-free process. For electrical connection of up to eight layers through-hole electroplating is recommended.

Systems for Multilayer Production

Downloads

Brochure

8-Layer Multilayer in Your Own Lab – LPKF MultiPress S4 (pdf - 271 KB)

Brochure

LPKF MultiPress S4 (pdf - 146 KB)

Brochure

LPKF Multilayer Technology for the Laboratory (pdf - 459 KB)

Catalog

Rapid PCB Prototyping Product Catalog (pdf - 3 MB)

TechGuide

LPKF TechGuide Rapid PCB Prototyping (pdf - 3 MB)