The first choice for SMT stencil manufacturers

Stencil manufacturers depend on efficient production processes. This means a perfect combination of high-speed, top-level-accuracy and trusted repeatability. LPKF StencilLaser technology itself plays a key role here. But there is more: One of the most important points is a deep understanding of the stencil application. Our LPKF experts for stencil cutting are happy to help you with your projects.

Optimum results

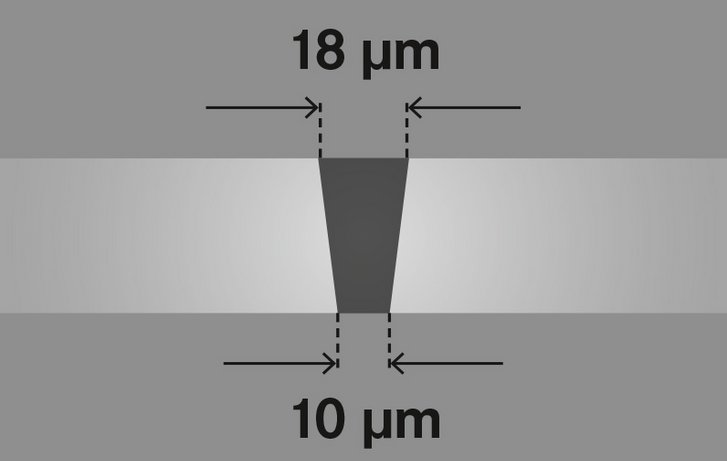

Stencil apertures with defined properties are essential for perfect solder printing results. LPKF StencilLasers are capable of cutting sheets from 20 μm up to 1 mm. The pictures below show exact geometries with nearly burr-free stainless steel (30 µm stencil sheet). Steep or tapered sidewalls with equally smooth surfaces, as displayed in the pictures below, result in optimum paste release.

Step stencils

Step stencils allow the exact adjustment of the solder paste volume on differently sized contact surfaces. A step stencil is a special SMD stencil shape that features local recesses (step-down) or bumps (step-up). This allows assembly of a circuit board with semiconductor components having little pitch or with rugged connection components in one work step.

Commitment and innovation

LPKF has been introducing innovations in electronics manufacturing for more than 30 years. With the LPKF StencilLaser a new form of electronics manufacturing in 1992 was established. Even today we continue to be the gloabal market leader in SMD stencil manufacturing.

Investment in capital equipment is a big deal. LPKF StencilLaser systems are designed from the ground up to be safe and successful. The LPKF stencil cutting systems enable the stencil business to provide the highest performance, quality and reliability to their clients.

LPKF not only supplies the laser systems but also offers expert service and support around the clock. The supplied software meets the requirements of stencil technology. Our ambition is to offer the most productive and precise equipment – at the cutting edge of development. That is what our engineers and technicians are committed to. Performing “Made in Germany” at its best.

Micro-cut parts made from metal foils and sheets

With the new LPKF PowerCut 6080 it is also possible to cut sheets up to 4 mm (150 mil) in thickness, e.g. stainless steel, aluminum, tantalum and copper.

Extended application option

The LPKF flatbed frame features a stable support grid consisting of a number of pointed support posts. The metal sheets are laid on the grid for laser cutting. Thick sheets in particular can be laid flat, helping the laser to remain focused on the material surface across the entire working area

Options and accessories

LPKF StencilCheck inspects the quality of SMT stencils. The software produces an optical scan of the stencil using a conventional PC scanner, and compares it with the production data. Any discrepancies are graphically shown on the screen. All of the test results are compiled in a report which is available for tracing to support seamless quality management.

The LPKF ZelFlex Z4P is a unique patented pneumatic four-sided stretching frame for quick and uniform clamping of SMT metal stencils.

ZelFlex Protect is a high-quality reusable stencil frame system that saves time and money. Frameless stencils can be mounted directly into the frame system without the need for glue or mesh. Uniform tension is applied through a unique air bladder system that provides continuous tension in all directions without requiring a permanent air connection.

Traditional framed stencils have many disadvantages. The mesh relaxes and the tension changes; each stencil is mounted at a different angle to the frame; the frame takes up a significant amount of storage space; and old-style frames use epoxy and must be recycled. The ZelFlex Protect Reusable Stencil Frame system is a cost-effective and environmentally friendly alternative to glued stencil frames.

![[Translate to Englisch:] Application](/fileadmin/mediafiles/_processed_/7/c/csm_LPKF_1410_Application_SL_TF_022_5e930bf7dd.jpg)