Your benefits with LPKF's new CleanCut and short pulse technology

LPKF's CleanCut technology works in the optimum pulse duration range for PCB material processing. Within the short pulse regime the pulse duration plays a major role in processing efficiency. Industrial applications in which the total processing time is important benefit significantly from using specialized laser technology.

New LPKF PicoLine laser systems

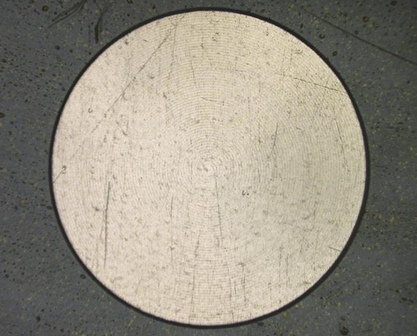

Clean cuts and precise vias – Surpassing industrial standards.

Based on the MicroLine platform, LPKF has developed a solution for meeting even higher demands on laser manufacturing quality: LPKF PicoLine. With this new laser system, LPKF meets the highest expectations regarding quality and cutting speed.

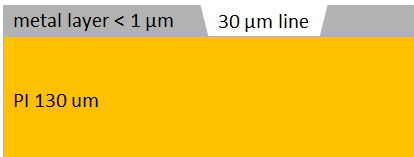

The system increases yield and production efficiency in PCB processing – resulting in fast return on investment. Equipped with a pico-second laser, the ultra-short pulse laser system LPKF PicoLine 5000 stands for highly precise positioning and accurate processing of PCB materials such as FR4 and PI-, LCP-, and PTFE-FPC in all industry-standard panel sizes.

Due to the CleanCut shortpulse technology, the heat-affected zone (HAZ) of the material becomes negligible.

Fields of application

LPKF has developed laser microvia processes to work with a very wide range of materials and via shapes to fit your designs and need for process efficiency.

Advantages

- Space savings

- Circuit reliability

- RF line termination

- Clean, smooth side walls

Typical Materials

- Liquid cristal polymers (LCPs)

- Polyimide (PI)

- Polytetrafluoroethylene (PTFE)

We are capable of handling other materials and compounds if your design calls for them. Please let us know what your requirements are.

Laser skiving is a selective ablation process that can remove one material with or without affecting an underlying material. Laser skiving can be performed to clear all dielectric material or to stop without cutting all the way through. Please also see "ablation of inorganic material from organic material."

Consulting and Sample Support

LPKF’s mission is to provide a long-term, trusting business relationship with all of our customers. We engage potential customers by offering to process custom sample panels. This initial panel evaluation is to assure all parties that the LPKF laser will meet the potential customer’s requirements for cycle-time, accuracy, precision and quality.

Learn more about our global service network with fast response times in the service section. Various concepts for extended warranty and care-free maintenance contracts are available.

Choose from the LPKF system portfolio

Various laser options and levels of system capabilities allow you to find the right balance between cost and quality. Both for special applications and for high-volume production LPKF laser processing equipment is highly productive.

- The systems work as standalone units or as components of fully integrated production lines.

- The systems can be adapted to various handling requirements of the electronics industry.

- Portfolio includes UV-lasers, green lasers and IR-lasers.

- LPKF MicroLine systems work with pulse durations in the nano second range.

- LPKF PicoLine systems work with pulse durations in the pico second range.