Complex Glass Processing With an Ultrashort-Pulse Laser

In glass structuring, it’s important that the surrounding structure not be damaged during the processing steps. Mechanical processes often lead to microcracks or impede optical analysis. With etching processes, a challenging chemical environment is required for the etching process itself as well as the lithographic processes.

The LPKF ProtoLaser R4 works with laser pulses in the picosecond range at a wavelength of 515 nm. It can cut and therefore also drill glass substrates. The minimum diameter corresponds to the radius of the laser beam – this makes it conceivable for creating electrical connections in SMT chips. For larger holes, circles of any desired diameter or free contours can be cut out. With direct glass structuring, drilled holes or contour cuts are possible.

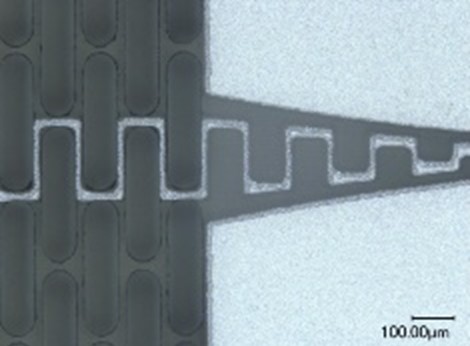

But that’s not all the ProtoLaser R4 can do: In extensive test series, it proved to be able to engrave glasses with a precision of a few nanometers. This opens up entirely new fields of application in physics, chemistry, and biology. In-house prototyping creates carriers for investigations in the submillimeter or submicrometer range or with extremely small amounts of fluids. Suitable system parameters enable ablation without thermal effects in or on the glass. Even the optical properties of the glass substrate remain practically intact.

Coatings on glass are ablated with a precision of approx. 10 µm. This applies to thick and to thin layers – both are applications in which the glass substrate remains untouched.

The parameters for numerous processing processes are included in the library that comes with the layout software. This greatly simplifies the post-design process control. It takes just one hour to go from the design to the finished prototype – that was never possible before with glass processing. Instead of having to perform several individual steps, the LPKF ProtoLaser R4 only requires the CAD design in order to structure the workpiece in the laser chamber.

The complete German article appeared in the journal "Mikroproduktion" , issue 1-2/22.