Information

Solder mask and legend printing for in-house prototyping

The solder resist is - especially with SMT components - a basic requirement for safe soldering. With LPKF ProMask, a professional solder resist mask can be quickly and effectively applied to already structured circuit boards.

The solder resist mask is printed from the CAD program onto a transparent foil, transferred to the printed circuit board and developed. In just four steps, the structured circuit board is given a perfect surface finish in just a few minutes for soldering without short circuits.

The legend printing follows the same principle: ProMask and ProLegend are supplied with all necessary tools and consumables for a perfect result.

LPKF ProMask and LPKF ProLegend are essential for fast, simple and cost-effective PCB prototyping or small series production. A photographic exposure process transfers all structures or lettering exactly to the printed circuit board.

The advantages of LPKF ProMask:

- Fast, simple and cost-effective

- Clean electrical insulation

- Perfect protection of the printed circuit board against corrosion and oxidation

The advantages of LPKF ProLegend:

- High adhesive strength against cleaning agents

- Simple procedure like LPKF ProMask

- Minimum letter height of 2 mm

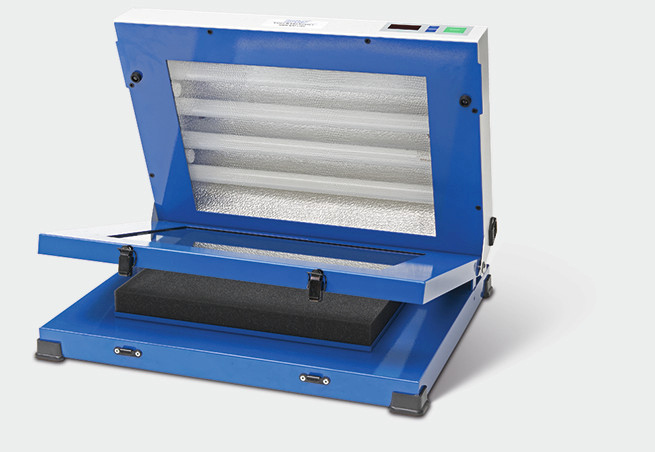

![3. expose the photo template [Translate to Englisch:] Fotovorlage belichten](/fileadmin/mediafiles/_processed_/8/7/csm_ProMask--016_57131793fe.jpg)

![4. developing and curing the solder resist mask [Translate to Englisch:] Entwickeln und Aushärten der Lötstoppmaske](/fileadmin/mediafiles/_processed_/3/d/csm_ProMask--028_021b9e536c.jpg)