Research & In-house PCB Prototyping

Shaping the future of technology

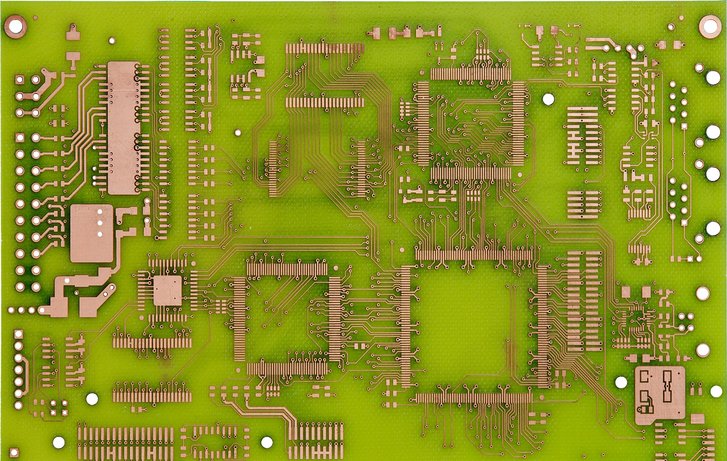

In-house production of printed circuit board prototypes

In the development of new products, the time factor is critical. Security of in-house data also plays a major role. From idea to mass-produced goods in minimal time with in-house rapid PCB prototyping. Develop a printed circuit board, manufacture it in just one day, and keep all data in-house: can this be done even faster and more securely?

Micro material processing

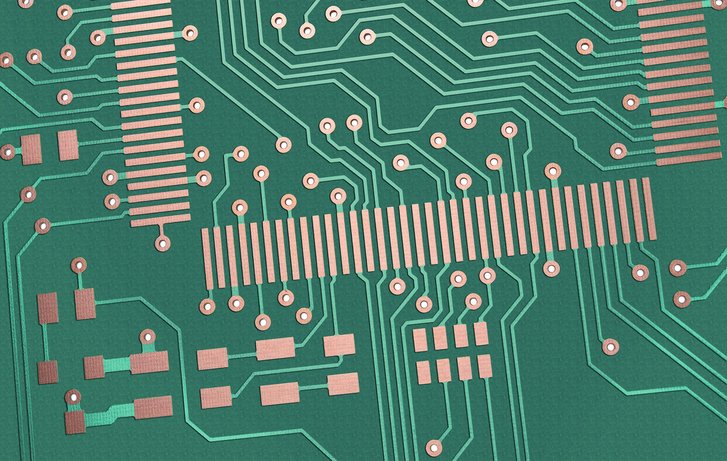

Development of electronic components has been progressing at an astounding pace for years. Integrated circuits are becoming more compact, and at the same time clock speeds are increasing. High frequencies, steep rising edges, and minimal space place huge demands on the printed circuit board. The response has been to use new substrate materials, which are much more difficult to process than the standard FR4 material is. Laser systems from LPKF Laser & Electronics are universal tools for micro material processing, but they can do much more than just machine substrates for printed circuit boards!

Process Steps for PCB Prototyping

Then feel free to contact us. We look forward to hearing from you.