Nutzentrennen von Leiterplatten mit unserer innovativen Lasertechnologie

Mit unseren Systemen auf Basis innovativer Lasertechnologie können wir Ihnen das flexibelste und hochwertigste Verfahren zum Trennen von Leiterplatten anbieten. Mehr über das Laser-Nutzentrennverfahren selbst, die vielfältigen Vorteile und die erreichbare technische Sauberkeit erfahren Sie auf den folgenden Seiten:

Höhere Performance bei geringeren Kosten

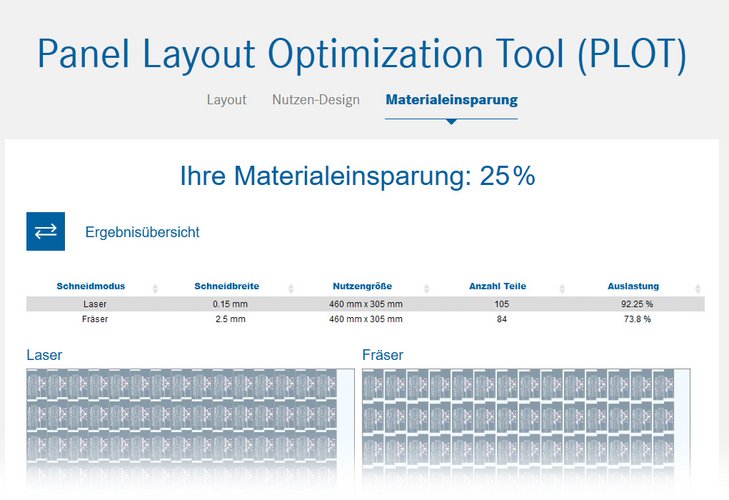

Mit dem Panel-Layout-Optimierungstool von LPKF können Sie Ihre individuellen Materialeinsparungen berechnen, wobei dies Ihnen die Vorteile des Lasers im Gegensatz zum Fräser aufzeigt.

Die Nutzentrenner von LPKF sind auf die zunehmende Automatisierung und die Anforderungen von Industrie 4.0 ausgerichtet und können mit skalierbaren und zugeschnittenen Lösungen ausgestattet werden.

Das richtige Design eines Panels spielt eine wichtige Rolle bei der kosteneffizienten und fehlerfreien Fertigung von Leiterplatten. Bei der Gestaltung ist es sehr hilfreich, die wichtigesten Richtlinien und Randbedingungen zu berücksichtigen. Um das zu ermöglichen haben wir die wichtigsten Regeln für Sie zusammengestellt, die Ihnen dabei helfen das perfekte Design für Ihre Anwendungen zu finden.

Sie interessieren sich für unsere Nutzentrenner?

Hier gelangen Sie zu unserer Produktübersicht, in der alle unsere Nutzentrennmaschinen vorgestellt werden. Dort erfahren Sie mehr zu den wichtigsten Spezifikationen, Gemeinsamkeiten und Unterschieden unserer Systeme. Auf diese Weise finden Sie schnell die passende Lösung für Ihre Anwendung!